Akao Technology

Balance of quality and speed

The slab (ingot) produced by the major rolling mill manufacturer boasting both quality and speed is 20 to 30 tons per.

The slab we manufacture is 1 to 2 tons, and the strength of Akao is condensed here.

We are realizing small lot and short delivery time with reliable quality and small slab with our DC casting manufacturing method.

Minimum lot 300 kg ~, manufacturing lead time only 3 weeks ~.

We support the Japanese manufacturing industry with detailed service as well as Q (quality), D (delivery date), and C (cost).

Video: Until aluminum products are made

Commentary

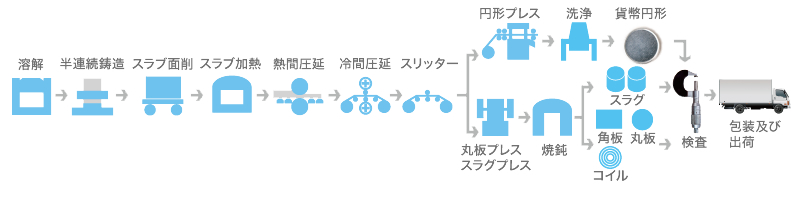

① Dissolution

Dissolve the aluminum ingot in an energy saving type melting furnace equipped with regenerative burner (exhaust heat recovery device).

② Semi-continuous casting

Perform chemical composition adjustment and cleaning treatment of molten metal and manufacture slab (ingot) with a vertical semi-continuous casting machine.

③ Hot rolling

Grind the segregation layer on the slab surface and roll it to the specified plate thickness after heating for homogenization.

④ Cold rolling

Prepare automatic plate shape control device, automatic thickness control device with X-ray, and manufacture high precision aluminum coil.

⑤ Slitter

Cut the width of the coil product.

⑥ Press line

Punch out the slug material in the high-speed forward press line.

⑦ Annealing

Heat treatment is performed to adjust the mechanical properties (hardness).

⑧ Inspection

Perform shipment inspection such as chemical composition and mechanical properties.

⑨ Shipping

Packed according to specifications and shipped to users.